Description

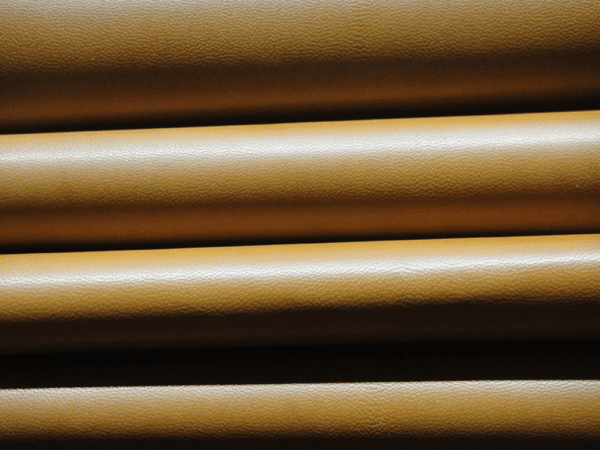

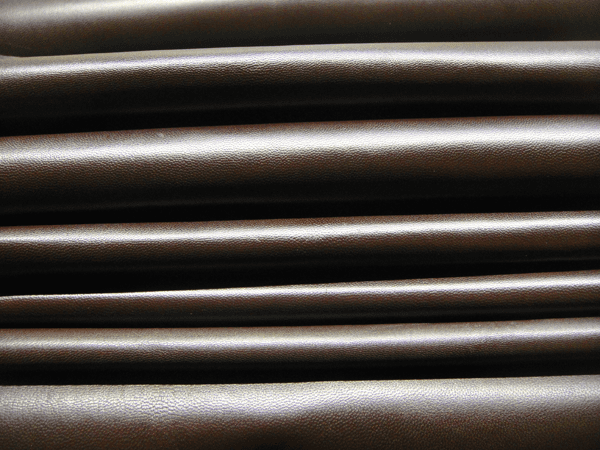

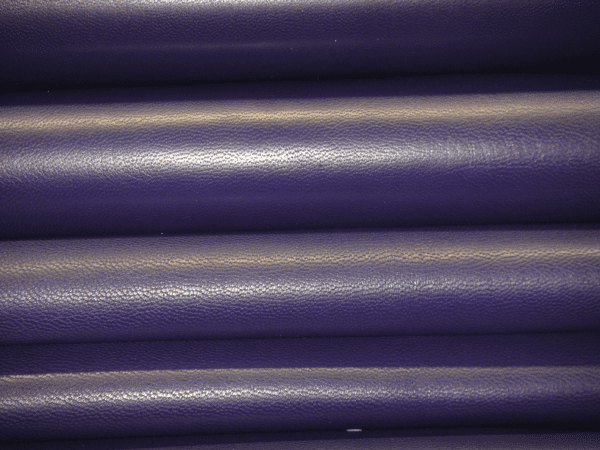

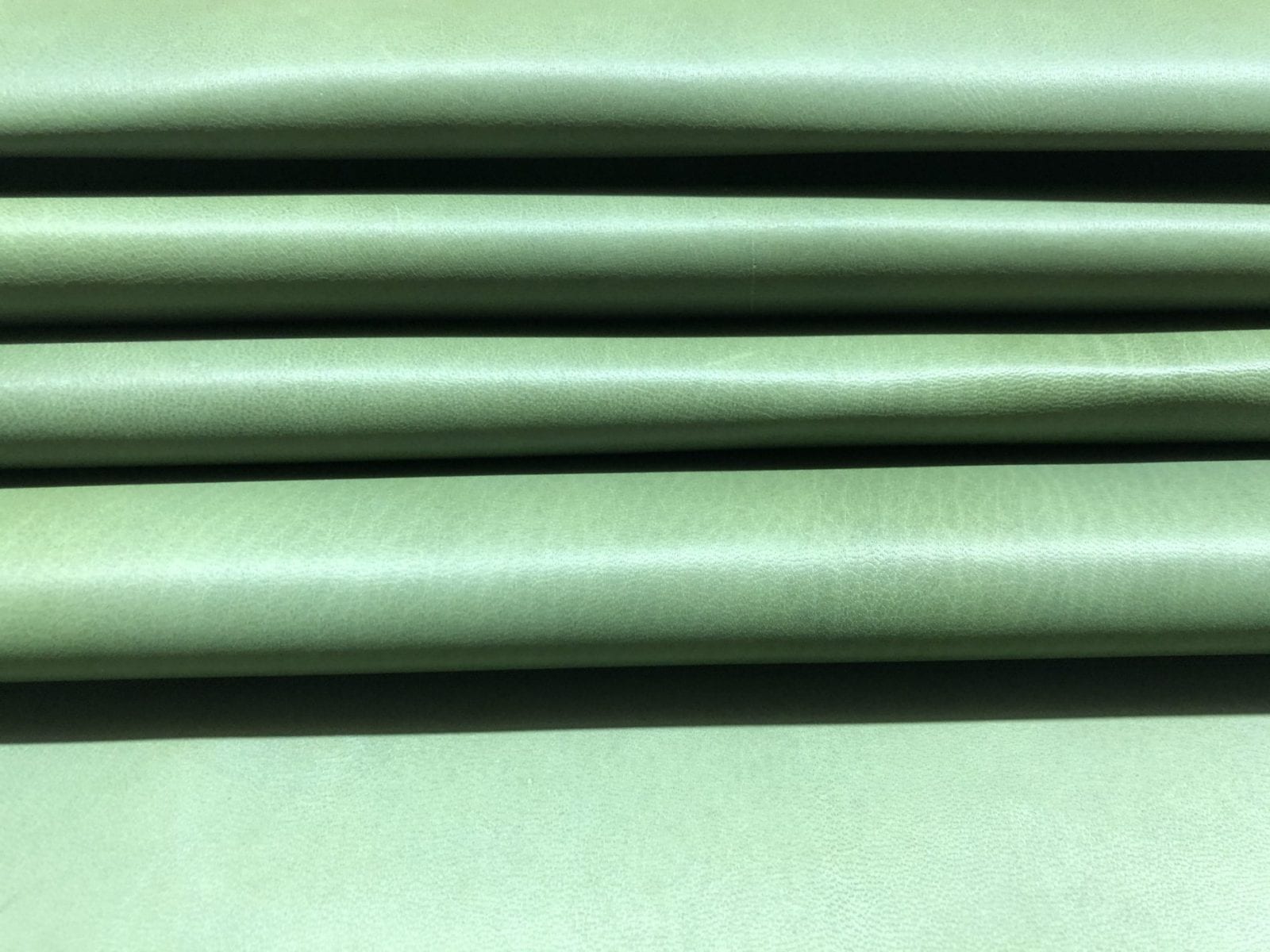

Our Smooth Historical Goat is a unique product that captures the essence of traditional leather making, embodying the artistry of the past. Exquisitely crafted by Siegel, this premium leather comes from pristine goatskins that have been expertly preserved during tanning without any grain manipulation or embossing. The result aligns perfectly with the standards laid out in the Report of the Society of Arts’ Committee on Bookbinding.

This product is named “Historical” to reflect the time-honored techniques employed during its creation, which refrain from plating or grain manipulation, yielding a smooth, calf-like grain. This meticulous process necessitates impeccable raw stock, as any inherent flaw becomes more pronounced. Importantly, we use NO OPAQUE FINISHES to conceal imperfections. We’ve learned through history that mechanical plating or glazing can damage the epidermis of the leather, shortening its lifespan. The grain of the Smooth Historical Goat is naturally exquisite, not enhanced by plating or glazing. Our skins are carefully selected for their lightweight yet expansive size, ensuring excellent cutting.

For products like this, we purchase the skins “in the hair”, providing us with control over de-hairing, tanning, and finishing processes, all of which affect the leather’s longevity. The resulting goatskin is as smooth as calfskin, making it extremely popular among bookbinders.

Our fine-grained skins undergo a careful selection process, are drum-dyed, and lightly coated with pigment to create a consistent color. We ensure no covering of defects, maintaining the grain’s natural texture. With a 100% vegetable tannage, it’s important to note that we use no opaque finish to mask defects; the leather’s natural grain is fully visible, demanding excellent grain selection.

As with all our products, our Smooth Historical Goat comes with an unconditional satisfaction guarantee. The substance ranges from 0.60-0.75 mm. Custom colors are available upon request with a minimum order. We also welcome edition orders.

Our leather is priced per skin. Grade #1 skins have no defects within 1 1/2″ of an edge, while Grade #2 may have defects that prevent the entire hide from being cut as one large, rectangular panel. Each skin accommodates minimum pattern sizes of 11 x 17, or larger.

Sizes range as follows:

- 30-39 sq dm = 3.22-4.20 sq ft

- 40-49 sq dm = 4.31-5.27 sq ft

- 50-59 sq dm = 5.38-6.35 sq ft

- 60-69 sq dm = 6.46-7.43 sq ft

For your convenience, skins are already pared to 0.6-.75 mm. This represents a cost-saving benefit as further paring won’t be necessary.